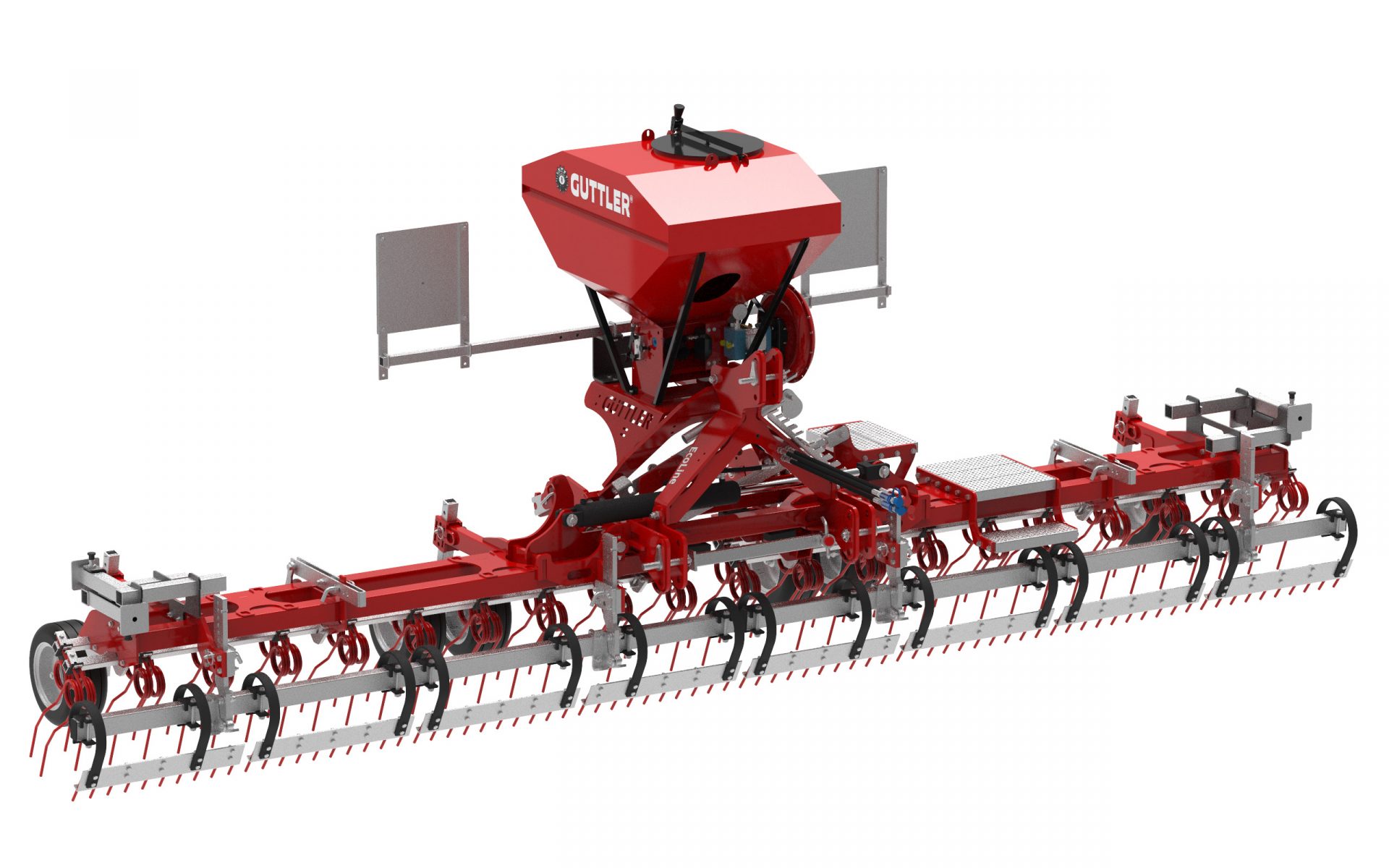

GreenMaster EcoLine 600

Many medium-sized companies have now outgrown the 3 m version and are looking for larger dimensions. This is exactly where the new Green Master 600 EcoLine comes in. The model combines a compact, coherent concept with proven components and deliberately focuses on a practical selection of equipment options. It therefore offers an economically attractive and affordable entry into the 6-meter class – without compromising on professional standards.

GreenMaster EcoLine 600

TECHNOLOGY

The new EcoLine version of the GreenMaster series is an ideal entry-level solution for small and medium-sized businesses. The lighter structure, in combination with the two-part folding system, makes the machine particularly suitable for use on pure grassland farms.

- 2-part folding

- Slim structure

- Lighter

- Can be parked when folded

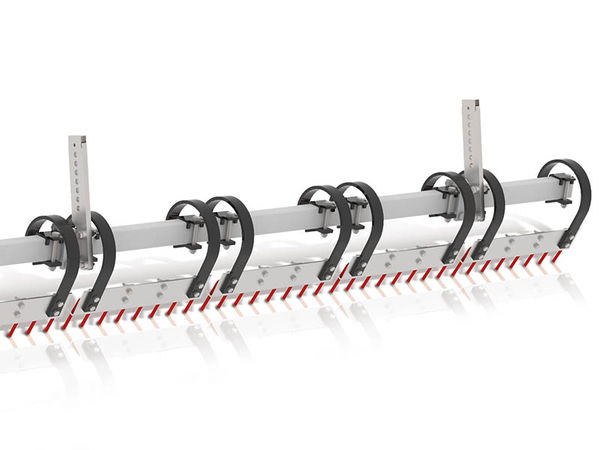

Outstanding harrow properties and modular extension principle. The aggressiveness of the GreenMaster harrow can be variably adjusted. The entire machine can be adjusted in no time at all in four simple steps. Simple and clever: the tine loss protection.

- GreenMaster harrow with robust NonStop tines 12 mm

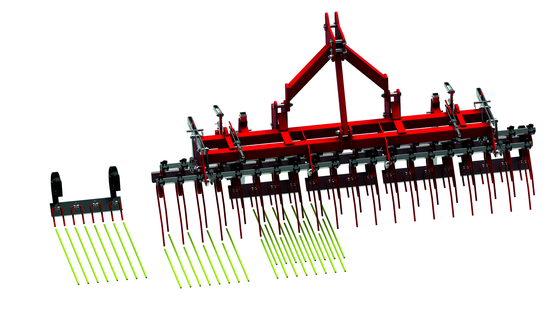

- Optionally with leveling rail or ripperboard (patent application)

- The ripperboard doubles the number of tines and halves the tine spacing (“the shortest four-bar harrow in the world”)

- Pneumatic spreader EPS 5 with 410 l

- Blower: electric

- Can be combined with the self-cleaning trailed rollers: OffSet®, Mayor and Master

WITH RIPPERBOARD: "The shortest 4-bar harrow in the world!"

- Doubles the number of tines working on the ground and thus achieves the performance of a 4-bar harrow

- The compact design of the machine does not change by one centimeter! This is important because of the coupling of heavy rollers.

- Doubling of the scarifying effect, sensitively adjustable from “zero” to “maximum”

- Also suitable for leveling molehills

- Can be retrofitted at any time, even if the machine was originally equipped with a leveling rail

Ground adaptation due to long-stroke tines

Of course, there are also unevennesses within one of the two movable frame segments. The harrow tines on our machines have a very long stroke and are therefore able to follow any unevenness sensitively.

TECHNICAL DATA

| Typ | Gewicht |

|---|---|

| Komplettsumme GreenMaster EcoLine 600 | |

| GreenMaster Striegel 600 (mech. Striegelverstellung) + ES 600 + EPS 410 Liter elektrisch | 1.210 kg |

| GreenMaster Striegel 600 (mech. Striegelverstellung) + RB 600 QUINTO + EPS 410 Liter elektrisch | 1.290 kg |

Standard equipment

- 2 rows of NonStop spring tines Ø 12 mm, line spacing 75 mm

- Tine loss protection

- Hydraulic folding

- 4 single support wheels

- Three-point tower cat. 2

- Warning signs with LED lighting

- Preparation of sowing technology (console) for mounting pneumatic spreader

- Support feet for parking in transport position

- Working width 6.00 m I Transport width 2.40 m I Transport height 3.20 m (with ground clearance 0.25 m)

OPTIONS

GreenMaster 600 combined with Mayor 640 for seedbed preparation

Leveling, crumbling and reconsolidating – this is what the GreenMaster with combined forage roller does in arable farming.

This means:

- Medium-heavy soils can often be prepared for sowing with the GreenMaster combination alone.

- Heavy clay soils may need to be prepared with suitable equipment and the GreenMaster combination then puts the finishing touches to the perfect seedbed.

In any case: enormous area coverage, moderate wear and low diesel consumption!

To control the common panicle: Unhook the roller - harrow solo!

The common panicle is a real space hog and feels particularly at home in damp meadows with a high proportion of clay and humus. Nutrient-rich moorland soils are also a good home for it.

Frequent cutting, manure application and compaction promote the spread of the common panicle. It can certainly be tolerated in small proportions, but if it spreads too much it forms a dense felt of grass, suppressing our valuable grasses and clover. The yield decreases and the feed value also suffers.

The common panicle should only be controlled after the first cut, as it still provides sufficient quantity in the first growth. Control should take place in late summer or early fall. Don’t wait any longer and increase the quality of your basic feed!

And how do I get rid of the common panicle once it has established itself?

✳️ Harrowing

✳️ Swath & depart

✳️ Re-seeding

For combing out the common panicle with Güttler GreenMaster:

Unhook the roller and aggressively harrow solo several times crosswise. This means you can work quickly and maneuverably and the common panicle remains loose.