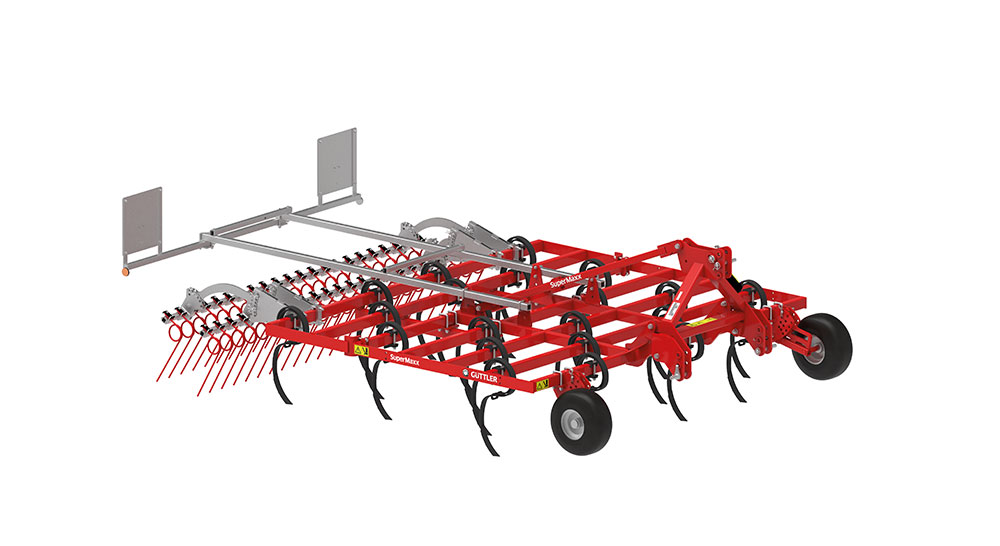

Super Maxx® 30-90 BIO

TECHNOLOGY

Super Maxx® BIO - the innovative concept from Güttler, without roller

Gentle on the ground:

- Flat, water-saving stubble cultivation with huge area output and moderate fuel consumption

- effective mechanical weed control and real “weed cures” by preparing a “false seedbed” and repeated shallow cultivation(NEW!Goosefoot coulters 200 mm)

- damp floors before ordering and allow to flash off first. Afterwards, the order can be carried out in a way that is gentle on the ground!

Soil-friendly: water-saving stubble cultivation, even on dried-out, hard soils

A shallow stubble cultivation repeated several times, preferably immediately after the combine.

- creates a thin layer of mulch from soil, stubble and straw. This prevents the evaporation of valuable soil water.

- the greenhouse climate under this layer of mulch

- allows volunteer cereals and weeds to emerge quickly.

- keeps the soil life (e.g. earthworms) going

- during the next operation, the emergence is mechanically destroyed (goosefoot coulter 200 mm as an option)

- no stool is buried, rather it is decomposed close to the surface by the active soil life.

Comparing the Super Maxx® to the conventional heavy cultivator you will notice

- double area output

- half fuel consumption (approx. 5 liters/ha)

- two passes with the Super Maxx® do not cost you more time and money than one pass with the classic heavy cultivator, and with better results!

Gentle on the soil: effective mechanical weed control

Effective mechanical weed control:

- The Super Maxx® loosens the weeds from the soil.

- The harrow frees the root system from adhering soil.

- The weeds dry up and die quickly.

This enables regular “weed cures” on a predominantly mechanical basis. Subsequent herbicide treatment becomes more successful. In this way, you avoid the formation of resistance in conventional farming. In organic farming, this lays the foundation for the later use of the harrow or hoe!

Second row harrow (option)

- perfect leveling

- even better straw distribution

- even more effective in weed control

- Can be retrofitted at any time

NEW!: Goosefoot coulters 200 mm

The line spacing of the tines is 130 mm.

Effective mechanical weed control with large area performance and moderate fuel consumption.

Gentle on floors: Pull up damp floors and allow to flash off!

Often we have to deal with too wet soils. Whether in early spring on silt-rich soils that dry poorly, in the absence of winter tillage, or mulch seeding in the fall when soils no longer dry. In these cases, it would be advisable to open the floor first so that it can ventilate. Reconsolidation takes place during seeding, when the soil has dried, with a front roller from GÜTTLER®. The clods break along their live obstructions. Result: stable soil structure, ideal gas exchange, rapid soil warming. In short, an ideal seedbed!

Gentle on the ground: light tractors with moderate front ballast

The innvovative concept without roller

- allows the use of light tractors

- gets by with moderate front weights

- makes you fast and agile on the wall!

- protects the tractor and your valuable soils!

In this example: The light 4-cylinder tractor manages without front weight with the Super Maxx® 50 – 5 BIO!

Tines 70x12 or 45x12 with double leaf spring???

We use tines of dimension 45×12 with double blade suspension with progressive characteristic!

The resistance of tines in comparison:

- Dimension 45×12 mm alone = 100%

- Dimension 70×12 mm = 156

- Dimension 45×12 + double leaf spring = 200 %!!!

- The double leaf spring also gives the tines lateral support!

Our tines convince with their progressive charateristics:

- When working flat, they generate a lot of fine earth with high-frequency vibrations

- With deep machining up to a maximum of 15 cm, they have the necessary stability, even laterally!

They have proven themselves in considerable numbers since 2007! Also on hard, dried clay soils as well as under stony conditions!

- Narrow line spacing of only 13 cm

- Ground clearance under the tine array 56 cm

The Super Maxx® masters even dried-out, hard soils!

The Super Maxx® tines have a strong self-traction due to their narrow coulters and their position directed towards retraction. This means that the Super Maxx® does not have to weigh a lot to be able to reliably pull into tightly packed floors. Even in the extreme summers of 2018 and 2019, with their often enough concrete-hard dried-out soils, the Super Maxx® never let us down! The tines go working depths up to 15 cm at any time!

TECHNICAL DATA

| Type | Working width | Transport width | Weight |

|---|---|---|---|

| 5-rows | |||

| Super Maxx® 30-5 BIO | 2.85 m | 3.00 m | 785 kg |

| Super Maxx® 50-5 BIO | 4.80 m | 2.50 m | 1,440 kg |

| Super Maxx® 60-5 BIO | 5.80 m | 2.50 m | 1,630 kg |

| Super Maxx® 90-5 BIO | 8.85 m | 3.00 m | 3,500 kg* |

| 7-rows | |||

| Super Maxx® 30-7 BIO | 2.85 m | 3.00 m | 880 kg |

| Super Maxx® 50-7 BIO | 4.80 m | 2.50 m | 1,635 kg |

| Super Maxx® 60-7 BIO | 5.80 m | 2.50 m | 1,815 kg |

| Super Maxx® 70-7 BIO | 7.10 m | 2.50 m | 2,185 kg |

| Super Maxx® 90-7 BIO | 8.95 m | 3.00 m | 3,560 kg* |

* Observe the permissible axle loads of the tractor! The auxiliary landing gear is required for driving on public roads.

In terms of pure tractive effort, there is no difference between the 5- and 7-bar Super Maxx® , as the number of tines is identical. A 100 hp tractor will therefore pull a Super Maxx® 50 – 7 BIO as well as a 50-5 BIO. While he can safely handle the 5-beam unit with moderate front ballast, much more front ballast could be required on the 7-beam Super Maxx® due to its longer overall length. For reasons of soil protection, we therefore recommend selecting a tractor one size larger for the 7-beam Super Maxx® than for the 5 beam of the same width.

Standard equipment

- Front swing arm support wheels 18.5 x 8.5-8

- Harrow with tines Ø12 mm

- Warning signs with LED lighting

- Cat.2 lower link hitch (rigid on Super Maxx® 3 meters)

- Six front support wheels (on Super Maxx® 90-5/90-7 BIO)

- Hydraulically foldable (on Super Maxx® 90-5/90-7 BIO)

- Expert opinion for obtaining the general. Operating permit required for driving on public roads (for Super Maxx® 90-5/90-7 BIO)

OPTIONS

- second row harrow

- Narrow shares 5 cm with carbide coating

- Goosefoot coulter 200 mm

- Protective tarpaulin for the tines for road travel (STVZO)

- reinforced front support wheels for extremely stony conditions

- Rear support wheels plus slotted hole adapter for the top link

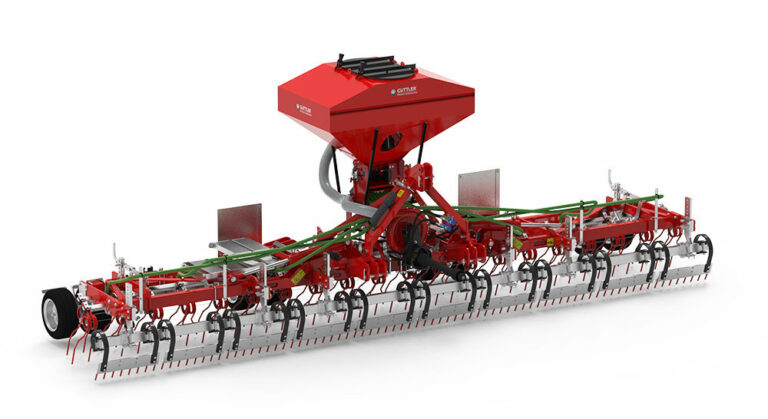

- Pneumatic seeder 410 liters, with hydraulic fan, for intercrops

Super Maxx Bio for intercrop incorporation

PICTURES

VIDEOS

DOWNLOADS

First-class stubble cultivation, favorable price A customer report from the John family from Eiken (CH)

We have made high demands on our new soil tillage machine. Efficient and high-performance stubble cultivation was just as important to us as working the desired working depth in both wet and dry conditions.

With the Super Maxx® large spring tooth harrow from GÜTTLER® we have found the optimal machine.

The 5 meter wide machine fits perfectly with our 100 hp tractor. The performance is ingenious with up to 3.5 ha/h. We drive a working depth of 7 to 15 cm, which can be precisely adjusted via the support wheels at the front of the machine.

Due to the tine distribution over the five beams, the machine never clogs even when stubble cultivating under our conditions and leaves a level and fine crumbly soil structure.

All three of us are excited about the concept of no trailing. No sticking, low machine weight and very good mechanical weed control. The soil dries excellently and retains its structure.

We can subsequently work faster and less deeply with the saw combination and thus save costs. And what’s great: the narrow transport width (only 2.40 m) and the extremely easy and safe parking position of the machine.

The advantages over a disc harrow or a cultivator? Quite clearly, working with the Super Maxx® is trouble-free even in damp conditions. It is ideal for use on slopes because there is no displacement of material. In addition, it has greater power with a smaller tractor. And all this at a sensational price / performance ratio.