GreenMaster Compact 600

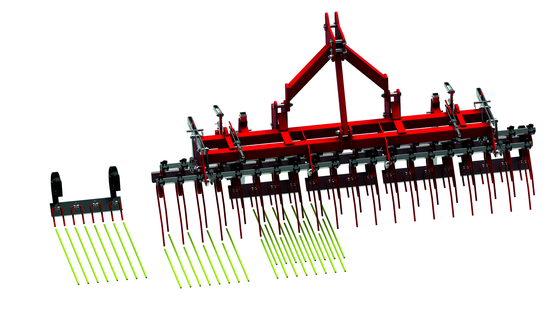

This model is the compact further development of the proven GreenMaster basic model. On this GreenMaster model, the medium-heavy Mediana prism roller is permanently attached to the harrow.

GreenMaster Compact 600

TECHNOLOGY

The new GreenMaster Compact gives you maximum efficiency in the smallest of spaces. The harrow field in combination with the proven Mediana Prismatic Roller® ensures optimum grassland maintenance in just one pass. The machine’s compact design makes it particularly versatile, making it the perfect solution for smaller structures and contractors.

- Compact design

- Modular design

- Powerful concept, even in smaller area structures

- Caster wheels possible

The GreenMaster harrow is variably adjustable in its aggressiveness. The entire machine can be adjusted in no time at all in just four steps. Simple and clever: the tine loss prevention system.

- GreenMaster harrow with robust NonStop tines 12 mm

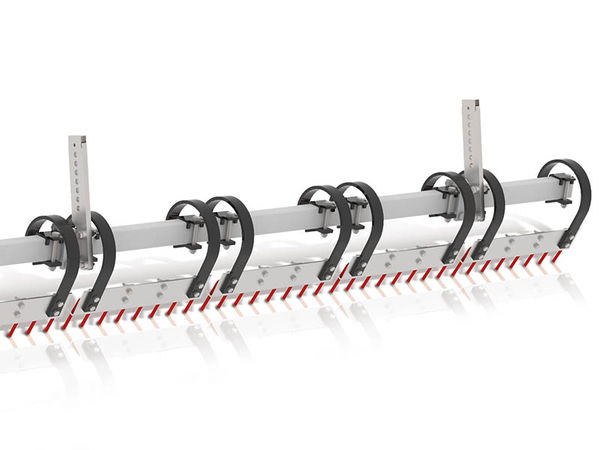

- Optionally with leveling rail or ripper board (patent application)

- The Ripperboard doubles the number of tines and halves the tine spacing (“the shortest four-bar harrow in the world”)

- Pneumatic spreader EPS 5 with 410 l

- Blower: hydraulic or electric

WITH RIPPERBOARD: "The shortest 4-bar harrow in the world!"

- Doubles the number of tines working on the ground, achieving the performance of a 4-bar harrow

- The compact design of the machine does not change by one centimeter! This is important because of the coupling of heavy rollers.

- Doubling of the scarifying effect, sensitively adjustable from “zero” to “maximum

- Also suitable for leveling molehills

- Can be retrofitted at any time, even if the machine was originally equipped with leveling rail

Ground hugging due to long stroke tines

Of course, there are also unevennesses within one of the two movable frame segments. The harrow tines of our devices have a very long stroke and are therefore able to sensitively follow all unevenness.

TECHNICAL DATA

| Typ | Gewicht |

|---|---|

| Komplettsumme GreenMaster Compact 600 | |

| GreenMaster Striegel 600 (mechanische Striegelverstellung, mechanische Walzenverstellung) + RB 600 QUATTRO + EPS 410 Liter hydraulisch, SeedProfi Basic | 3.720 kg |

| GreenMaster Striegel 600 (mechanische Striegelverstellung, hydraulische Walzenverstellung) + RB 600 QUATTRO+ EPS 410 Liter hydraulisch, SeedProfi High | 3.720 kg |

| Komplettsumme GreenMaster Compact 800 | |

| GreenMaster Striegel 800 (mechanische Striegelverstellung, mechanische Walzenverstellung) + RB 800 QUATTRO + EPS 410 Liter hydraulisch, SeedProfi Basic | 3.750 kg |

| GreenMaster Striegel 800 (mechanische Striegelverstellung, hydraulische Walzenverstellung) + RB 800 QUATTRO+ EPS 410 Liter hydraulisch, SeedProfi High | 3.800 kg |

Standard equipment

- 2 rows of NonStop spring tines Ø 12 mm, line spacing 75 mm

- Fork loss prevention

- Hydraulic folding with pressure equalization

- Integrated prismatic roller® Ø 33/38 cm

- Three-point tower cat. 2 and 3

- Warning signs with LED lighting

- Preparation of sowing technology (console) for mounting pneumatic spreader

- Support feet for parking in transport and working position

- Working width 6.0 m I Transport width 3.0 m I Transport height 3.10 m (with ground clearance of 0.25 m)

OPTIONS

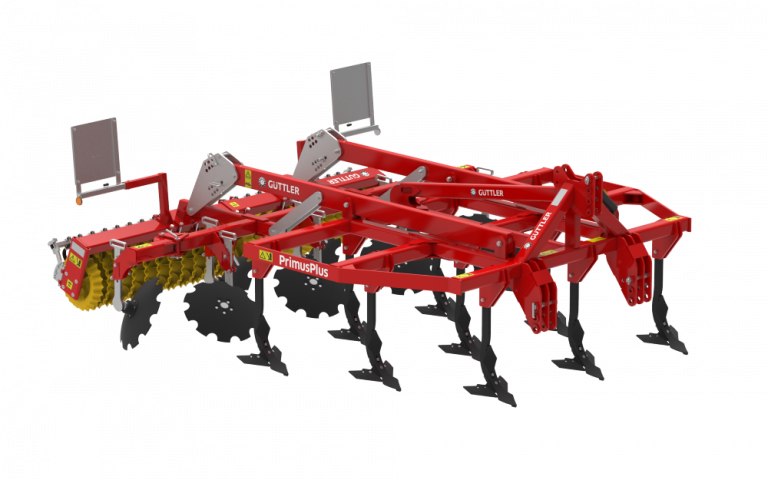

GreenMaster 600 combined with Mayor 640 for seedbed preparation

Leveling, crumbling and reconsolidating – that’s what the GreenMaster with combined loader roller does in arable farming.

This means:

- Medium-heavy soils can often be made ready for seeding with the GreenMaster combination alone.

- Heavy clay soils may need to be prepared with suitable equipment and the GreenMaster combination then takes over the “finishing touch” to the perfect seedbed.

In any case: Enormous area performance, moderate wear and low diesel consumption!

To control the common panicle: Unhook the roller - groom solo!

The common panicle is a real space robber, it feels particularly well on moist meadows with high clay and humus content. Nutrient-rich peat soils also provide a good home for it.

Frequent cutting, manure application, and compaction promote the spread of common panicle. It can certainly be tolerated in small proportions, but if the spread is too severe it forms a dense grass felt, suppressing our valuable grasses and clover. The yield decreases and the feed value also suffers.

Common panicle should be controlled only after the first cutting, as it still provides sufficient quantity in the first growth. Control should be done in late summer or early fall. Don’t wait any longer and increase the quality of your basic feed!

And how do I get rid of the common panicle once it is established?

✳️ Harrowing

✳️ Swath & depart

✳️ Reseeding

For combing out common panicle with Güttler GreenMaster:

Unhook roller and aggressively groom solo several times crosswise. So you are fast and agile at work and the common panicle remains loose.