EXPERIENCE REPORTS

FIRST-CLASS STUBBLE PROCESSING. FAVORABLE PRICE.

We have made high demands on our new soil tillage machine. Efficient and high-performance stubble cultivation was just as important to us as working the desired working depth in both wet and dry conditions. With the SuperMaxx® large spring tooth harrow from GÜTTLER, we have found the optimal machine.

The 5 meter wide machine fits perfectly with our 100 hp tractor. The performance is ingenious with up to 3.5 ha/h. We drive a working depth of 7 to 15 cm, which can be precisely adjusted via the support wheels at the front of the machine. Due to the tine distribution over the five beams, the machine never clogs even when stubble cultivating under our conditions and leaves a level and fine crumbly soil structure.

All three of us are excited about the concept of no trailing. No sticking, low machine weight and very good mechanical weed control. The soil dries excellently and retains its structure.

We can subsequently work faster and less deeply with the saw combination and thus save costs. And what’s great: the narrow transport width (only 2.40 m) and the extremely easy and safe parking position of the machine.

The advantages over a disc harrow or a cultivator? Clearly:

Working with the SuperMaxx® is trouble-free even in damp conditions. It is ideal for use on slopes because there is no displacement of material. In addition, it has greater power with a smaller tractor. And all this at a sensational price/performance ratio.

MULTI-TALENT OF GRASSLAND MAINTENANCE AND RENEWAL

Soil: loamy sand to marsh

Grassland area: about 600 ha

Corn borer control: approx. 200 ha

Machine combination: Tractor (190 hp) + GÜTTLER HarroFlex 600 grassland harrow and Matador 610S prismatic roller

Contractor Münster has been engaged in the service of grassland maintenance and renewal for a long time. In order to make progress in this area, various systems were tried out. They came across the GÜTTLER company through a contractor friend. The GreenMaster convinced everyone and finally the new GreenAlpin 600 could be taken delivery of.

Around 600 hectares of grassland are now cultivated annually with the machine combination. The trend is upward. “We can now do 4 operations with one pass,” says the company manager. The feedback from his customers is consistently positive. The seed is literally massaged into the intact crop by the prismatic roller. New seeding is also carried out with this combination. “The casserole is much more uniform and there is no streaking.”

MORE EFFICIENT GREEN LAND REGENERATION.

By chance, I got to know the GreenMaster from GÜTTLER® at an agricultural machinery exhibition. Even the demonstration there convinced me of the quality of the work. In just one operation, the machine completes the entire grassland renewal: currying, seeding and rolling.

This has also been demonstrated in our practice. In just one pass, we harrow to aerate the turf, place new grass seed, and roll the whole thing back on. This saves working time and fuel. With the 7.5 meter machine, we easily manage 4 hectares per hour at 10-12 km/h driving speed.

At the same time, the machine leaves a first-class working image. And: through regular grassland renewal, we get measurably more milk from the basic forage.

In connection with the greening requirements, this year we want to order a greening mixture with the GreenMaster on a trial basis on around 70 ha after the corn harvest. We also use the device for corn borer control. The only downside is that the wide device has to be folded out for parking. This then takes up a lot of space in the machine hall. Otherwise, we are satisfied all around. We have absolutely backed the right horse.

Heinfried Sudmann is plant manager at Wiechring-Sudmann KG, Diepholz. The farm keeps around 1,000 dairy cows and has been cultivating around 400 hectares of grassland and arable land with the GreenMaster grassland combination since 2014.

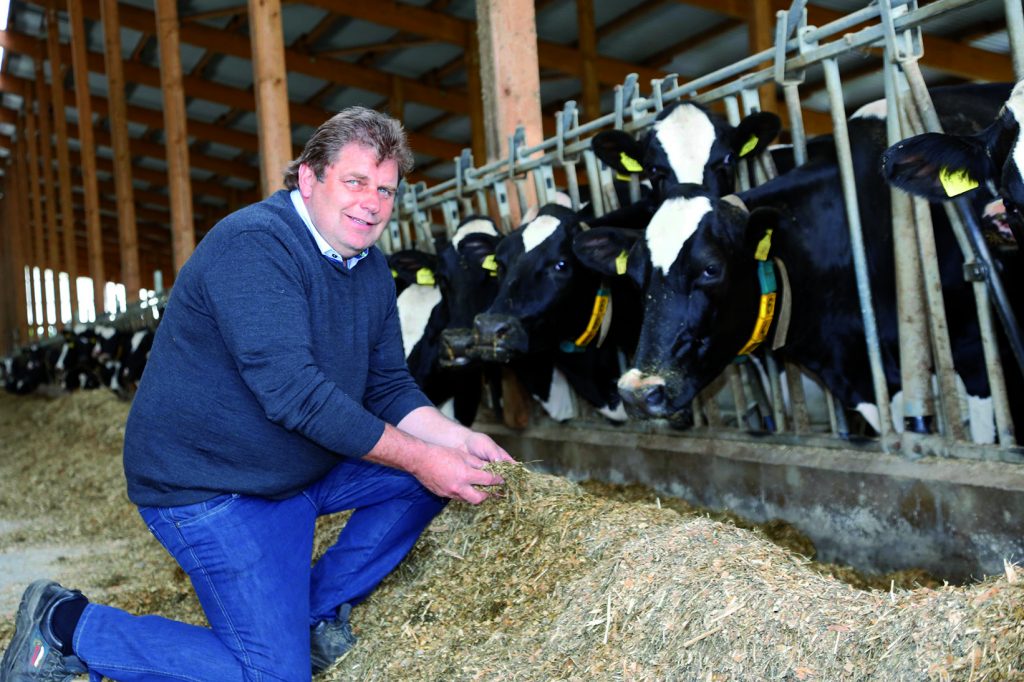

More milk from the basic forage – regular grassland renewal has paid off.

MULTI-TALENT IN FRONT OPERATION.

As a contractor, I see the biogas boom with one eye crying and one eye laughing: the areas under combine harvesters have declined rapidly. In turn, the single-grain sowing of corn has grown. In doing so, I have found time and time again that the reconsolidation of the seedbed by farmers is completely different.

Therefore, I was looking for a front packer that I could combine together with the 8-row precision air seeder. During the tests, the Matador roller from GÜTTLER® convinced me. Firstly, it replaces the “dead” front ballast on the tractor. On the other hand, it creates an optimum, even seedbed in sandy soil thanks to the large ring diameter of the Prism roller®. Even with 10 mm of precipitation, after waiting an hour in our sandy soil, I can continue sowing corn.

In practice, the Matador has become a real all-rounder. For grassland reseeding I lend the roller. It is coupled to the rear hydraulics with the seed tank mounted.

The grassland harrow from GÜTTLER® is installed in the front linkage. This means that the team is well balanced. On the level, a 120 hp tractor at six meters working width is enough. The good work results of the machine combination quickly got around. I had not expected such a high demand for grassland renewal. This has enabled me to gain additional new customers.

The Matador roller has also proven its worth in corn borer control. Combined with the harrow, it ran on about 500 ha in 2012 to control the pest. Even in direct comparison with a special device for beetle control, the Matador was able to convince with equally good results.

TODAY WE MILK 5,050 KG OF MILK FROM THE BASE FEED.

How can grassland yield be significantly increased? Matthias Heckenberger has shown the way. The 27-year-old master farmer and winner of the 2015 Ceres Award (Young Farmer category) runs a dairy and arable farm in Biberach. The greatest increase in performance came from the improvement of grassland.

Various methods were tested.

The young farmer describes the most successful as follows: “We comb the areas three times with the GÜTTLER harrow. The common panicle is driven off. Overseeding is done after the first cut with the GÜTTLER combination 6 m harrow and reseeding technique and the GÜTTLER roller”. 222.2 dt of dry matter was thus harvested in 2015 – compared to 99.78 dt in 2013. And the basic feed efficiency has also been significantly improved. “Today we are milking 5,050 kg of milk from the base feed,” says Heckenberger with satisfaction. “And save costs”. Concentrate consumption has dropped from 430 g/kg milk in 2008 to 225 g. Welcome side effect: Healthier animals, remount rate more than halved to 20%!

PROVEN ON ARABLE LAND AND GRASSLAND

Johannes Sams, Neumarkt am Wallersee, Austria, reports:

“We reseed our grassland regularly. However, re-rolling with the smoothing roll only produced unsatisfactory results. Since we have been using the Matador 30 E/S, the ascents have been right.

We also notice the tillering stimulation by the roller. New seedings also succeed very well.

In the meantime, we are also rolling all seeds with the Matador in arable farming and achieving very high and, above all, very uniform field emergence, which we did not know before. Despite 1300 mm of precipitation per year, silting is not an issue.

My initial skepticism has since given way to the conviction that this was a worthwhile investment!”